Ever wonder how your car can stop so quickly on Plano’s busy roads? Learn how your braking system works—from pedal to pads—covering key components like the master cylinder, calipers, and rotors. We’ll touch on modern technologies such as ABS and stability control, compare common brake setups (four-wheel discs, front disc/rear drum, and regenerative braking for hybrids/EVs), and share practical maintenance tips tailored to Plano driving—think stop-and-go around Legacy West, summer heat on US-75 and the Dallas North Tollway, and weekend runs up SH-121—plus fluid service guidance and clear emergency advice.

How Your Braking System Works

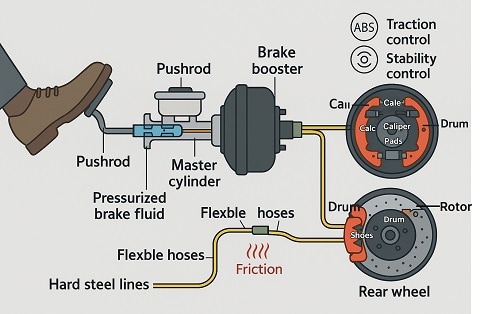

Press the pedal, and a pushrod moves the master cylinder’s pistons, converting your foot’s force into hydraulic pressure. The brake booster (vacuum or electric) multiplies that force so it doesn’t feel like leg day at the gym. Pressurized brake fluid travels through hard steel lines and flexible hoses to each wheel. There, calipers clamp pads against rotors (disc brakes) or wheel cylinders push shoes against a drum (drum brakes). Friction turns motion into heat, slowing the vehicle. On modern cars, electronic systems like ABS, traction control, and stability control monitor wheel speed and adjust pressure in milliseconds to keep you in control.

Key Brake Components You Should Know

Within one stop you’ll engage all the essentials: the master cylinder (creates pressure), brake booster (adds assist), brake fluid and hydraulic lines/hoses (carry pressure), calipers (fixed or floating bodies that convert fluid pressure into clamping force), pads (friction material), and rotors (iron or composite discs). Cars with rear drum brakes use wheel cylinders and curved friction shoes inside a drum, often with a self-adjuster for consistent pedal feel. Small parts—slides, pins, shims, anti-rattle clips, dust boots—keep everything aligned, quiet, and moving freely.

Master Cylinder & Brake Booster (Power and Pressure)

The master cylinder houses pistons and seals that send fluid to front and rear circuits (often diagonally split for safety). A tandem master gives redundancy: if one circuit fails, the other still works. In front is the brake booster: most use engine vacuum with a diaphragm to multiply your leg force; turbo, hybrid, and EV platforms frequently use electric or electro-hydraulic boosters for consistent assist and seamless integration with driver-assist features.

Brake Fluid, Lines & Hoses (The Lifeblood)

Brake fluid (DOT 3/4/5.1 glycol-based or DOT 5 silicone) is engineered to resist boiling and absorb moisture. Water contamination lowers boiling point and corrodes internals, so flush intervals matter. Hard lines are steel or copper-nickel for corrosion resistance; flex hoses bridge moving suspension parts. Any swelling, cracking, kinks, or leaks reduce braking authority and should be addressed immediately.

Calipers & Hardware (Turning Pressure into Clamp)

Floating (sliding) calipers are common and cost-effective; a single or dual piston pushes the inboard pad, and the body slides to pull the outboard pad into the rotor. Fixed calipers mount solidly and use pistons on both sides for even pressure and better pedal feel—common on performance cars. Multi-piston setups spread force across the pad for consistency and heat control. Clean, lubricated guide pins and intact boots prevent taper wear and dragging pads.

Pads: Organic, Semi-Metallic & Ceramic (Friction, Noise, Dust)

Organic (NAO) pads are gentle on rotors and quiet, but can fade with heavy use. Semi-metallic offer strong bite and heat tolerance, though they may be noisier and dustier. Ceramic pads are quiet, clean, and stable across temperatures, ideal for daily driving; extreme track use still favors specific high-temp compounds. Choose a formula that matches your reality—commuting, towing, mountain descents, or spirited canyon runs.

Rotors & Drums (Where the Heat Lives)

Most modern cars use vented rotors up front for cooling and solid or vented in back. Drilled or slotted designs help out-gas pad resins and refresh the pad face under severe use, but shouldn’t be a band-aid for cooling issues. Drilled rotors can be more crack-prone with repeated heat cycles. Drum brakes (often on rear axles of economy or compact vehicles) package an effective parking brake and can be durable, provided the self-adjuster works and the friction surfaces are clean.

Types of Braking Systems on Modern Cars

The mainstream setup is hydraulic disc brakes with ABS at all four corners. Performance systems add multi-piston fixed calipers, larger rotors, high-boiling fluid, dedicated cooling, and more aggressive pad compounds. Hybrids/EVs combine friction brakes with regenerative braking, where the drive motor becomes a generator to recover energy; software blends regen with friction seamlessly. Cutting-edge platforms use brake-by-wire (electro-hydraulic) to translate pedal inputs into computer-controlled pressure, enabling advanced driver assistance and consistent pedal feel even when regen is doing most of the work.

ABS, EBD & Brake Assist (Electronics That Keep You Safe)

ABS (anti-lock) cycles pressure rapidly to prevent wheel lock-up, preserving steering authority. EBD (electronic brakeforce distribution) adjusts front/rear balance as load shifts. Brake Assist detects panic stops and quickly ramps up pressure. In stability events, the system can brake individual wheels to help rotate or stabilize the vehicle, often working with traction and stability control.

Maintenance Schedule & What to Check

Make brake checks part of every oil change or tire rotation. Look for pad thickness (replace before the friction material hits 3–4 mm), rotor surface (no deep grooves, scoring, or heat spots), fluid level and color (amber, not dark or contaminated), hose condition (no cracks/bulges), and even wear on pads. Spin wheels for drag and apply the brakes to feel for smooth, linear stopping. On drums, confirm the self-adjuster moves freely and the shoes have even arc contact.

Measuring Pads & Rotors (Numbers That Matter)

- Pad thickness: Aim to replace at 3–4 mm remaining to avoid metal-to-metal contact.

- Rotor thickness: Compare with the minimum thickness (stamped on the rotor hat). Below spec means replace, not resurface.

- Runout & DTV: Excessive runout (wobble) or disc thickness variation creates pedal pulsation; correct with on-car machining (if within spec) or rotor replacement and thorough hub cleaning.

Brake Fluid Service & Bleeding

Moisture ingress is inevitable, so flush every 2–3 years (or per your owner’s manual) and anytime the system is opened. Use the correct DOT spec and avoid mixing incompatible fluids. Bleeding methods include pressure, vacuum, and two-person pump-and-hold. ABS modules sometimes require a scan-tool-activated bleed to cycle internal valves—especially after major repairs.

Proper Break-In (Bedding) & Seasonal Smarts

New pads and rotors need a controlled bed-in: a series of moderate stops to evenly transfer a fine layer of pad material to the rotor. This improves bite, consistency, and noise control. In winter, rinse wheels and brakes after salted roads to reduce corrosion; in mountainous summers, downshift to spare the brakes on long descents and prevent fade.

Common Signs Your Brakes Need Attention

Listen and feel. Squealing often points to wear indicators or glazed pads. Grinding means metal-to-metal contact—stop driving and repair immediately. A soft or spongy pedal suggests air or fluid degradation. A hard pedal could indicate booster or vacuum issues. Pulling under braking hints at seized slides, a sticking caliper, uneven pad deposits, or hose collapse. Vibration or pulsation in the pedal usually means rotor runout/DTV. Burning smells, smoke, or a wheel too hot to touch signal dragging brakes or severe overheating.

Repairs: Resurface or Replace? DIY or Pro?

- Pads: Replace as a set per axle and always service hardware—clean and lubricate slides, replace shims/clips, and verify free caliper motion.

- Rotors: Resurface only if the rotor will remain above minimum thickness and you can eliminate runout; otherwise replace. Always clean the hub face and rotor mating surfaces; a tiny rust flake can cause pulsation.

- DIY vs. Pro: Many pad/rotor jobs are DIY-friendly with the right tools and torque specs. Leave hydraulic leaks, ABS faults, seized bleeders, electric parking brakes, and brake-by-wire issues to a professional with a scan tool and service data.

Cost Factors & Smart Ways to Save

Total cost varies with pad compound, rotor design, labor time, and vehicle complexity (think multi-piston calipers or EPB systems). Save money by addressing issues early (preventing rotor damage), choosing parts that fit your driving needs (don’t overbuy track pads for city use), and bundling services (flush fluid when brakes are apart).

Driving Techniques That Help Brakes Last

Look far ahead to brake earlier and lighter, keeping heat down. Maintain safe following distances so you’re not “on-off-on-off” constantly. Use engine braking on long grades. Avoid resting your left foot on the pedal. After a spirited drive, give the brakes a gentle cool-down rather than parking with glowing hot rotors.

Emergencies & What to Do if Brakes Fail

If the pedal goes to the floor, pump it quickly to build pressure. Downshift to use engine braking, activate hazards, and apply the parking brake gradually to avoid a lockup—modern electric parking brakes can meter braking, but use caution. Steer to a safe shoulder and stop. Afterward, do not drive the vehicle until a full inspection finds and fixes the fault.

FAQs About Your Brakes

How long do brake pads last?

Anywhere from 20,000 to 60,000+ miles depending on driving, weight, terrain, and pad compound.

Do hybrids/EVs wear brakes less?

Usually yes—regenerative braking offloads a lot of work, but calipers still need periodic exercise and lubrication to prevent sticking.

Is ceramic always better?

It’s great for daily use (quiet/clean), but sustained track heat still favors dedicated performance pads.

When should I flush brake fluid?

Every 2–3 years (or per the manufacturer), sooner if it’s dark, contaminated, or after heavy thermal events.

Visit Huffines CDJR Plano For all Your Brake Needs

Modern braking systems blend proven hydraulics with smart electronics to deliver confident, controllable stops. Know the parts, watch for warning signs, and keep up with inspections, fluid service, and proper installation. You’ll enjoy shorter stopping distances, quieter operation, and a pedal that inspires trust every time you press it. If you have questions—or it’s time for an inspection—visit Huffines CDJR Plano for expert brake service and straightforward advice.

Image by Media Digital | Licensed with Unsplash License

Image by The DK Photography | Licensed with Unsplash License